This is EnkaSpacer

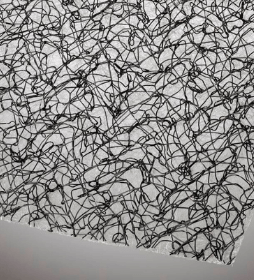

EnkaSpacer flow media are flexible, open-structured three-dimensional mattings. They can be produced from a range of different polymers. The flow medium consists of monofilaments which are thermally bonded together where they cross. EnkaSpacer provides over 95 % of void space.

EnkaSpacer flow media are flexible, open-structured three-dimensional mattings. They can be produced from a range of different polymers. The flow medium consists of monofilaments which are thermally bonded together where they cross. EnkaSpacer provides over 95 % of void space.

Depending on the requirements of the specific molding process and finished composite part, the matting can be delivered in different stiffnesses, shapes and thicknesses. Zig-zag and pyramid-shaped configurations are among the most widely applied EnkaSpacer variants.

Spacing achievable with the standard product portfolio ranges between 4 mm and 20 mm.

How EnkaSpacer is used in injection molding processes

Foam injection molding is a popular process applied throughout a number of industries. The automotive sector is one of the most popular examples. When used in combination with fibreglass reinforcement and decorative skins, complex lightweight parts can be produced economically. For more than 30 years EnkaSpacer has delivered an unrivalled performance in the production of such foam-cored composite parts. Because of its compression-resistant, yet flexible structure, the spacer completely fills even the most complex mold cavities with varying thicknesses. Here it acts as a spring and pushes the fiberglass reinforcement as well as the composite skin to the outer edges of the mold. It holds them in the correct position throughout the mold process. Its open, yet resilient structure lets the foam flow freely. EnkaSpacer ensures that the skins, fiberglass and core are fully wetted out. The product is one of the fastest foam-flow media available in the market today. It helps composite-part makers significantly reduce production time while enhancing the properties of the finished part. In many designs, EnkaSpacer improves its flexural strength and modulus of the part.

What makes EnkaSpacer the ideal flow medium for foam injection molding?

Features:

- Compression resistant, yet very flexible

- Different grades of stiffness available

- Product variants available made of a great variety of polymers

- High heat resistance

- Outstanding impact strength

- Excellent tensile strength

Benefits:

- Simple to use (no special equipment required)

- Does not require pre-molding

- Safeguards fast and regular flow of PU foam

- Avoids the inclusion of air

- Can be applied in strongly contoured parts

- Americas

- Asia Pacific

- Europe, Middle East & Africa

-

Consumables for resin infusion processesENKA®CHANNEL & ENKA®SPACERpdf 1MB

-

Spacer for reaction injection moulding processesENKA®SPACERpdf 2MB

-

Flow media and spacers for vacuum infusion and structural injection moulding[NEW] Solutions Overviewpdf 3mb